Everything About Oil Field Equipment and Pipeline Equipment: Trick Insights and Important Details

Oil field equipment and pipeline systems play a crucial role in the oil and gas industry. They are important for the efficient removal and transportation of hydrocarbons. Trick elements, such as drilling rigs and tank, directly influence operational success. Advancements in innovation pledge to enhance security and effectiveness. Understanding these aspects is vital for any individual associated with or curious about this intricate industry, as it establishes the stage for much deeper expedition of market techniques.

Summary of Oil Field Equipment

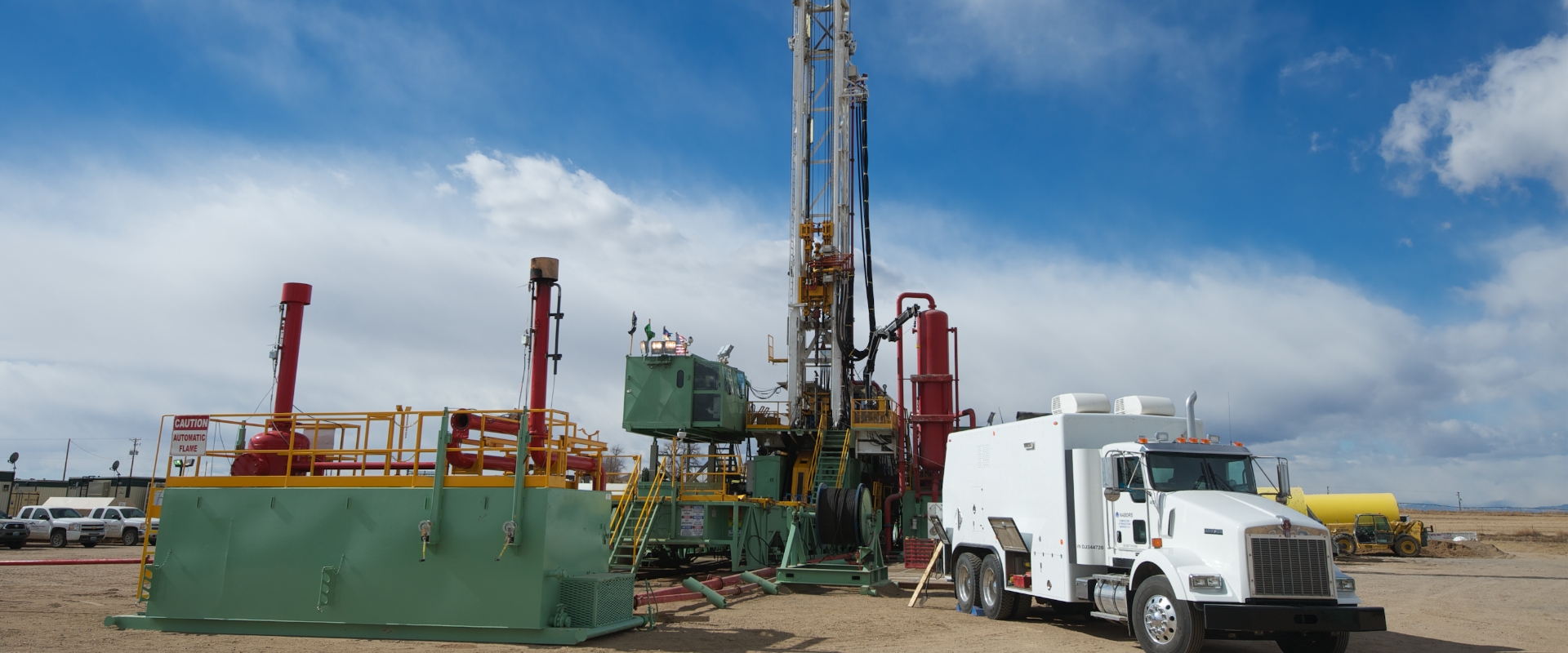

As the need for oil remains to grow, recognizing the devices used in oil areas becomes increasingly essential. Oil field equipment includes a variety of equipment and tools crucial for expedition, removal, and processing. Secret elements consist of piercing rigs, which are important for getting to oil tanks, and production tools, such as separators and pumps, that help with the removal process. Superior Oilfield Rentals Texas. In addition, tank play a considerable function in holding unrefined oil before transportation. Safety equipment, including blowout preventers and pressure gauges, ensures operational safety and security and efficiency. Each piece of tools functions cohesively to optimize production and keep effective workflow. Experience with this tools is very important for professionals in the market to guarantee effective operations and adherence to security requirements

Kinds Of Drilling Rigs and Their Applications

Drilling rigs function as the foundation of oil removal operations, with numerous kinds developed for details geological problems and operational demands. The most common types include rotary boring rigs, which use a rotating drill bit to penetrate the planet, and cable tool rigs, recognized for their percussion exploration method. For offshore procedures, jack-up rigs and semi-submersible rigs supply security and assistance in marine settings. Additionally, directional boring rigs enable drivers to drill at angles, getting to down payments that are not up and down accessible. Each gear type has special benefits, enhancing effectiveness and safety based on the exploration atmosphere. Choosing the appropriate gear is important for taking full advantage of source extraction while lessening ecological effect and operational costs.

Necessary Pipeline Equipment and Their Functions

Pipeline facilities is vital for the transport of oil and gas from removal websites to refining facilities and end-users. Different necessary equipment parts facilitate this process. Pipes themselves function as the primary avenues, made to hold up against high pressure and destructive substances. Pump terminals are vital for keeping circulation by increasing stress along the pipeline. Shutoffs play a vital function in managing flow and isolating sections for maintenance. Furthermore, fittings and connectors assure protected joints in between pipeline areas. Keeping track of systems, including circulation meters and pressure sensors, are important for finding leakages and optimizing circulation rates. Pigging equipment is used for maintenance and cleansing, securing pipeline stability and efficiency. Together, these components develop the backbone of a reliable pipeline system.

Advancements and Technologies in Oil and Gas Equipment

Safety And Security and Upkeep Practices in the Oil Industry

While the oil industry has actually made substantial strides This Site in technology and efficiency, the value of durable safety and security and maintenance methods can not be overstated. Effective safety and security procedures are important to secure employees and the environment, decreasing the threat of mishaps and spills. Regular evaluations and maintenance of equipment help recognize possible problems prior to they intensify, guaranteeing functional honesty. Training programs for staff members are vital, stressing the relevance of safety and security awareness and emergency action procedures. Furthermore, adherence to industry guidelines and criteria cultivates a culture of safety and security. Applying advanced surveillance technologies can better enhance upkeep methods, permitting for real-time analyses of equipment problems. Eventually, focusing on safety and maintenance is important to the sustainability and success of the oil sector.

Regularly Asked Inquiries

What Are the Environmental Effects of Oil Field Equipment?

The environmental effects of oil field equipment include environment devastation, water contamination, and air contamination (Superior rentals squeeze tools). In addition, tools malfunction can cause spills, adversely impacting wild animals and communities, highlighting the need for stringent policies and monitoring

How Is Oil Field Equipment Transferred to Remote Locations?

Delivering oil field equipment to remote locations commonly includes specialized automobiles, helicopters, or barges. Logistics business coordinate courses, making certain equipment shows up safely and effectively, taking into consideration surface and ease of access to reduce delays and maximize efficiency.

What Governing Requirements Govern Oil Field Equipment?

Governing criteria governing oil field equipment mostly include security, environmental management, and functional performance read review guidelines. Agencies such as OSHA and EPA apply these guidelines to guarantee secure techniques and decrease ecological influence in oil removal operations.

What Abilities Are Required to Run Oil Field Equipment?

How Do Oil Rates Influence Equipment Need and Usage?

Oil rates considerably affect equipment need and usage. Greater rates generally result in enhanced expedition and manufacturing activities, driving need for equipment. On the other hand, see this here reduced prices may cause minimized procedures and lowered demand for tools.